Parsons Green, London

5-storey mixed-use development

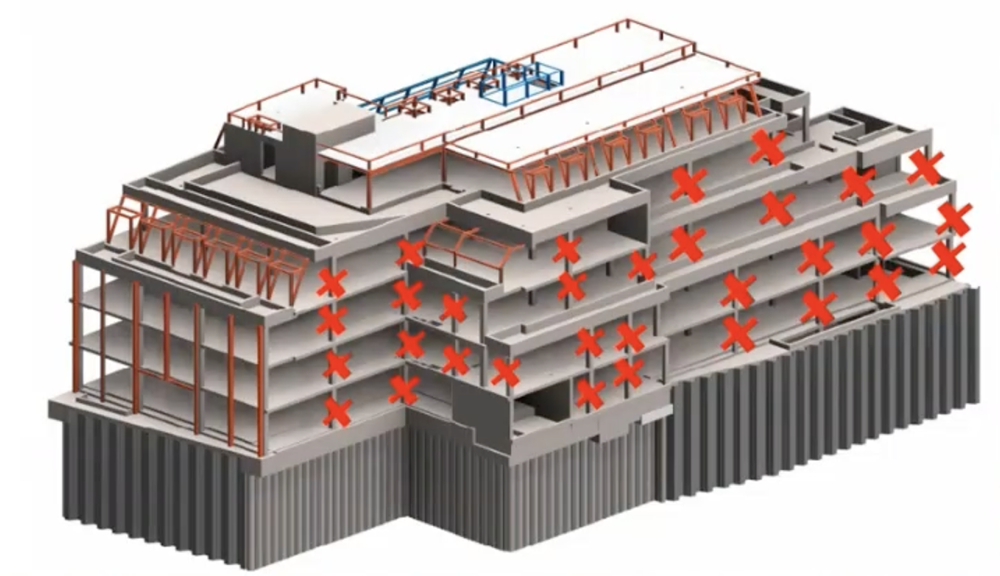

Urban construction is rarely constrained by design ambition alone. More often, the real limitations are access, space, sequencing, and risk. On tight city-centre plots, traditional construction methods struggle to cope with restricted deliveries, lack of storage, and the impact on neighbouring buildings. In these conditions, success depends less on individual components and more on how structure, façade, and logistics are integrated into a single buildable strategy.

Deprom’s Role: Rethinking the Façade as Part of the Structure

By taking this approach, a number of in-situ reinforced concrete columns were removed from the perimeter frame. The panels take on structural load, reducing reliance on perimeter beams and simplifying the overall construction sequence. This shift has a direct impact on buildability, particularly on a site where access, time, and space are all heavily constrained.

Logistics as a Controlled Process, Not a Risk

Quality remains central to the approach. Factory-controlled production ensures consistent brickwork and concrete finishes, removing weather-related risks and on-site variability. This allows the building envelope to become secure and weather-tight earlier in the programme than would typically be possible using traditional construction methods.The Result: Predictability Where It Matters Most

As the project continues on site, the benefits of treating the façade as a structural element are becoming clear. The programme is progressing ahead of expectations, with significant time savings anticipated and no requirement for external scaffolding.

What this project demonstrates so well is that precast sandwich panels aren’t just for tall buildings, but that they also deliver real value on sites where space, access, and timing are the real challenges.

Key project information

- Location: Parsons Green, London

- Development: 5-storey mixed-use

- Client: Legendre UK

- Planned precast elements: 213

- Façade area: 2,400 m²

- Sandwich panels installed: 185 units

- Programme saving: 8 weeks

- Façade system: Load-bearing three-layer sandwich panels

- Brick slips: 35 mm IBSTOCK Niveus

- External scaffolding: 0%